Photovoltaic panels are the key element of the solar bike: they convert the energy of the sun into electric energy that can be used directly by the engine and/or for charging the battery. When we start the adventure of building his solar bike, we are a little lost in front of the diversity of offers.

Photovoltaic panels are the key element of the solar bike: they convert the energy of the sun into electric energy that can be used directly by the engine and/or for charging the battery. When we start the adventure of building his solar bike, we are a little lost in front of the diversity of offers.

I will therefore share here several elements that can guide you and allow you to make a choice with full knowledge of the cause.

Flexible panels or rigid panels?

Flexible panels: this is the type of panel most frequently used for solar bikes. The reasons are their lightness (from 3 to 5 kg for 200W) and the good energy efficiency of the monocrystalline silicon cells that compose them (ratio between recovered electrical energy/solar energy received). More often than not, a supporting structure of the panels is added that rigidifies and protects them. In fact, every shock on a cell decreases its performance locally. With multiplied shocks, the total power of the panel decreases significantly and permanently. That is the weak point of flexibility.

Flexible panels: this is the type of panel most frequently used for solar bikes. The reasons are their lightness (from 3 to 5 kg for 200W) and the good energy efficiency of the monocrystalline silicon cells that compose them (ratio between recovered electrical energy/solar energy received). More often than not, a supporting structure of the panels is added that rigidifies and protects them. In fact, every shock on a cell decreases its performance locally. With multiplied shocks, the total power of the panel decreases significantly and permanently. That is the weak point of flexibility.

Rigid panels: they are sturdy, weatherproof like hail; they are planned a priori for a building installation. They are very heavy (15 to 18 kg for 200Wc). Their photovoltaic cells are often made of polycrystalline silicon with less energy efficiency than monocrystalline silicon. For these reasons, they are rarely used on solar bikes.

Rigid panels: they are sturdy, weatherproof like hail; they are planned a priori for a building installation. They are very heavy (15 to 18 kg for 200Wc). Their photovoltaic cells are often made of polycrystalline silicon with less energy efficiency than monocrystalline silicon. For these reasons, they are rarely used on solar bikes.

One exception, however: Christophe Dugué, who works at a French manufacturer, has built himself a rigid panel and light, monocrystalline. He experimented with it during the 2017 Sun Trip Tour. Stéphane Bertrand was also able to benefit this prototype during the 12,000 km of Sun Trip 2018. This summer, no doubt we will see these extraordinary panels again since Christophe Dugué and his wife participate in the Sun Trip Tour 2019. Unfortunately, these panels are not yet marketed.

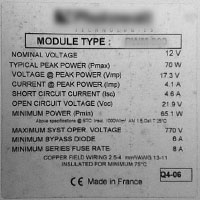

The electrical characteristics of the panels

The power of a panel is proportional to the number of photovoltaic cells that compose it. The photovoltaic cell is the basic unit of a panel, it produces an electrical power of the order of 3 Watts under a voltage of less than 1 volt.

The electrical characteristics are mentioned by the manufacturers. The main features are the operating voltage (VMP in volts) and the maximum current in the event of maximum sunlight (IMP in AMPS). Depending on the Assembly of the cells, in series and/or parallel, panels of the same power may have different operating voltages and maximum currents.

The electrical characteristics are mentioned by the manufacturers. The main features are the operating voltage (VMP in volts) and the maximum current in the event of maximum sunlight (IMP in AMPS). Depending on the Assembly of the cells, in series and/or parallel, panels of the same power may have different operating voltages and maximum currents.

The designer of a solar bike is therefore faced with an equation with many parameters influencing each other:

The designer of a solar bike is therefore faced with an equation with many parameters influencing each other:

- selection of the panel surface for the desired total power,

- choice of dimensions and where to install them according to the type of bike,

- serial or parallel installation depending on the solar controller (voltage and current),

- choice of type and number of regulators (MPPT boost or not).

Solar panel photovoltaic cells

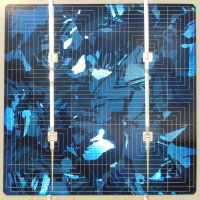

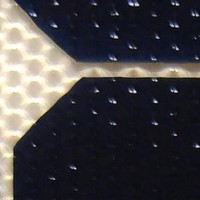

Two main types of cells can compose the panels. For a solar bike, because of the higher efficiency, it is the monocrystalline silicon that is most appropriate.

Monocrystalline silicon cells Monocrystalline silicon cells-very good yield, about 200Wc/m² -lifespan of ~ 30 years, -higher cost than polycrystalline silicon. |

Polycrystalline silicon cells Polycrystalline silicon cells– yield of about 150Wc/m², thus less than monocrystalline, -lifespan of ~ 30 years. -cost more economical than monocrystalline silicon. |

But it all depends on the user’s needs: Barnabas Chaillot, met during the prologue of Sun trip 2018, made the most economical choice [read more…].

The quality of photovoltaic cells

The performance of a panel depends on the quality of the photovoltaic cells that compose it but few panel manufacturers mention the “class” of the cells used. It strongly impacts the cost of construction of the panel, and therefore its selling price. For our use, three levels of cell quality are available:

“class A” cells: they are of very good quality, without visible defect and their electrical characteristics correspond exactly to the specifications defined by the manufacturer. The solar panels built with this cell class are therefore the most expensive. “class A” cells: they are of very good quality, without visible defect and their electrical characteristics correspond exactly to the specifications defined by the manufacturer. The solar panels built with this cell class are therefore the most expensive. |

“class B” cells: they are of good quality and have little visible defects. Their yield is close to or slightly lower than the “class A” cells. “class B” cells: they are of good quality and have little visible defects. Their yield is close to or slightly lower than the “class A” cells. |

“class C” cells: they show visible defects that affect their performance (e.g. chipped, cracked cells…). Their performance is obviously less good, these cells are used to realize the economic signs. “class C” cells: they show visible defects that affect their performance (e.g. chipped, cracked cells…). Their performance is obviously less good, these cells are used to realize the economic signs. |

“class D” cells: they present breaks or are incomplete. They can be resized to produce in smaller sizes, but most often their material is recycled to make new ones. “class D” cells: they present breaks or are incomplete. They can be resized to produce in smaller sizes, but most often their material is recycled to make new ones. |

More… All about the performance of photovoltaic cells!

Views: 190